Our advantage:

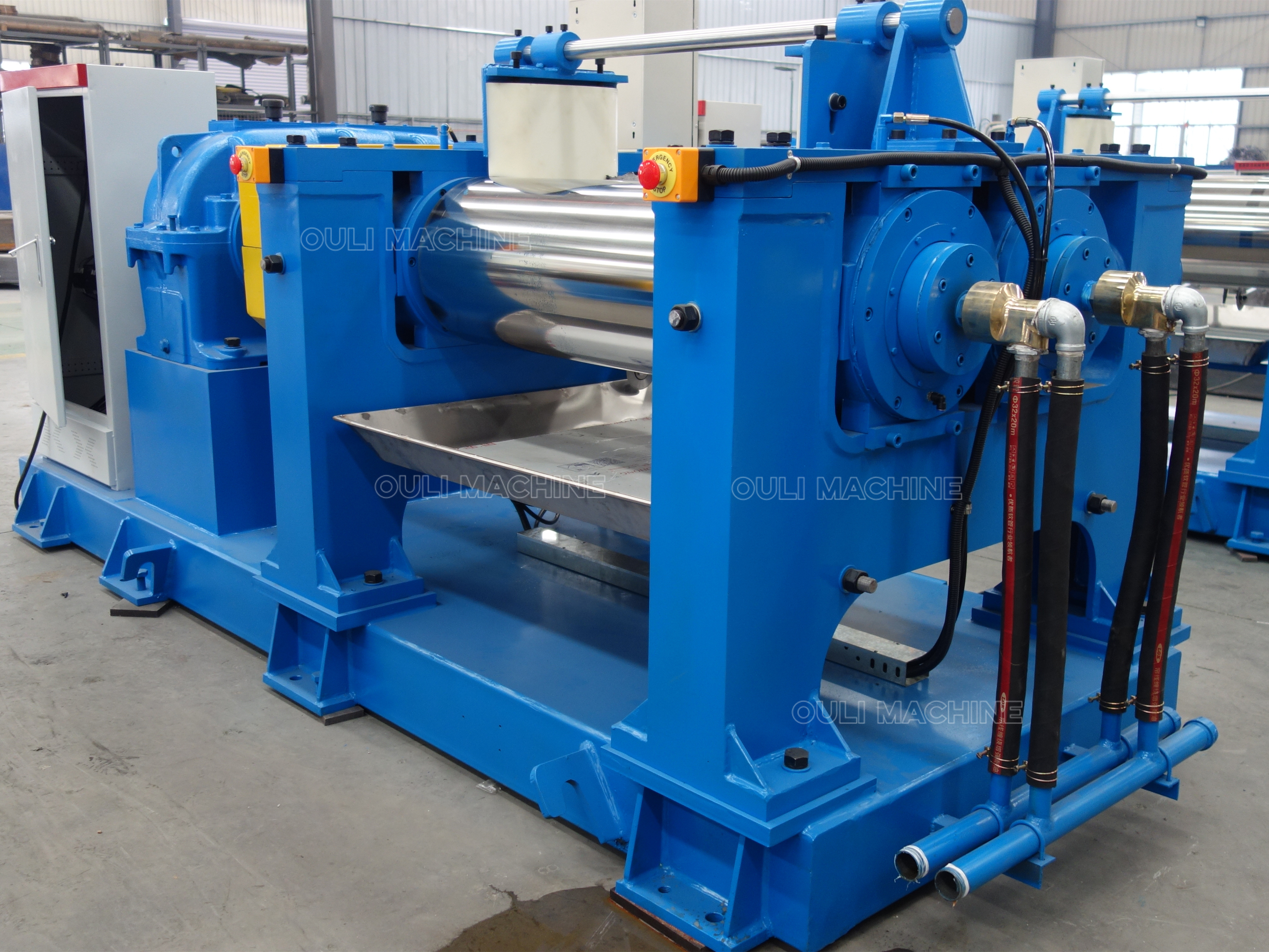

1. We make our user safe: brake time : 1/4 circle ,brake power:hydraulic brake, bar brake/chest brake/stop button/ foot brake.

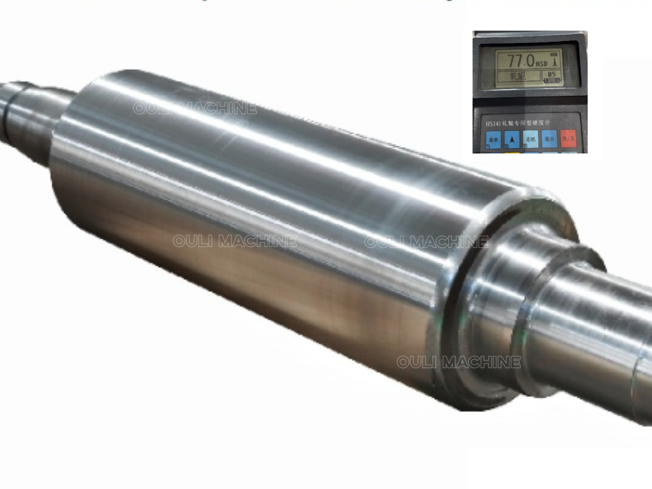

2. HS75 HARD ROLL & BEARING:The roller is made of LTG-H chromium-molybdenum or low nickel-chromium alloy chilled cast iron, centrifugally cast, the hardness of the chilled layer on the surface of the roller can reach 75HSD and the depth of the chilled layer is 15-20mm

3.Hard gear reducer: Gear type: high strength and low carbon alloy steel quenching tooth surface. Machining : CNC grinding processing, high precision. Advantage : high transmission efficiency, stable operation, low noise.

Technical parameter:

|

Parameter/model |

XK-160 |

XK-250 |

XK-300 |

XK-360 |

XK-400 |

|

|

Roll diameter(mm) |

160 |

250 |

300 |

360 |

400 |

|

|

Roll working length (mm) |

320 |

620 |

750 |

900 |

1000 |

|

|

Capacity (kg/batch) |

4 |

15 |

20 |

30 |

40 |

|

|

Front roll speed (m/min) |

10 |

16.96 |

15.73 |

16.22 |

18.78 |

|

|

Roll speed ratio |

1:1.21 |

1:1.08 |

1:1.17 |

1:1.22 |

1:1.17 |

|

|

Motor power (KW) |

7.5 |

18.5 |

22 |

37 |

45 |

|

|

Size (mm) |

Length |

1104 |

3230 |

4000 |

4140 |

4578 |

|

Width |

678 |

1166 |

1600 |

1574 |

1755 |

|

|

Height |

1258 |

1590 |

1800 |

1800 |

1805 |

|

|

Weight (KG) |

1000 |

3150 |

5000 |

6892 |

8000 |

|

|

Parameter/model |

XK-450 |

XK-560 |

XK-610 |

XK-660 |

XK-710 |

|

|

Roll diameter(mm) |

450 |

560/510 |

610 |

660 |

710 |

|

|

Roll working length (mm) |

1200 |

1530 |

2000 |

2130 |

2200 |

|

|

Capacity (kg/batch) |

55 |

90 |

120-150 |

165 |

150-200 |

|

|

Front roll speed (m/min) |

21.1 |

25.8 |

28.4 |

29.8 |

31.9 |

|

|

Roll speed ratio |

1:1.17 |

1:1.17 |

1:1.18 |

1:1.09 |

1:1.15 |

|

|

Motor power (KW) |

55 |

90/110 |

160 |

250 |

285 |

|

|

Size (mm) |

Length |

5035 |

7100 |

7240 |

7300 |

8246 |

|

Width |

1808 |

2438 |

3872 |

3900 |

3556 |

|

|

Height |

1835 |

1600 |

1840 |

1840 |

2270 |

|

|

Weight (KG) |

12000 |

20000 |

44000 |

47000 |

51000 |

|

Product delivery: