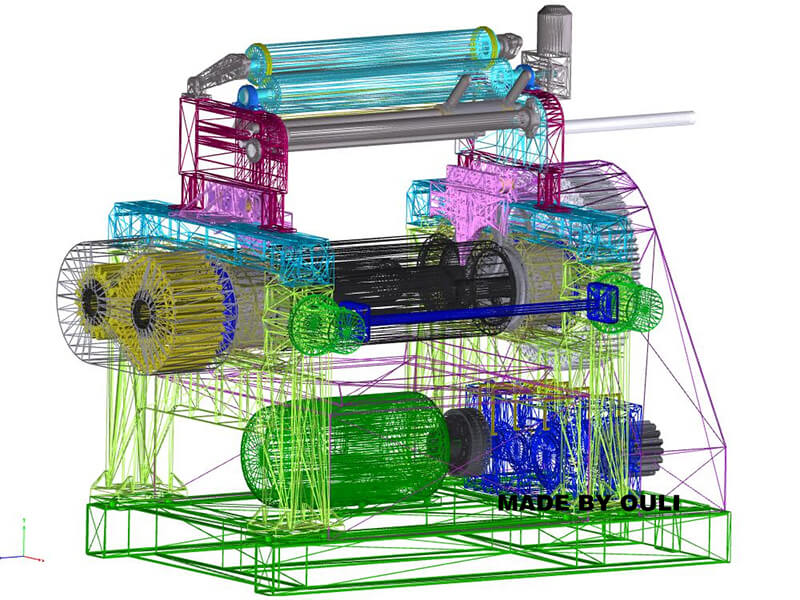

1, roller

a, the roller is the most important working part of the mill, it is directly involved in the completion of the rubber mixing operation;

b. The roller is basically required to have sufficient mechanical strength and rigidity. The surface of the roller has high hardness, wear resistance, chemical resistance and peeling resistance, and has good thermal conductivity to facilitate heating of the rubber compound. cool down.

c. The roller material is generally made of chilled cast iron, and the experimental small-size open mill roll is also made of medium carbon alloy steel.

2, roller bearing

The roller bearing mainly adopts two kinds of structural forms: sliding bearing and rolling bearing. The sliding bearing is the most commonly used one of the roller bearings of the open mill. It has the characteristics of simple structure, convenient manufacture and low cost.

Rolling bearings are characterized by long service life, low friction loss, energy saving, easy installation and easy maintenance. However, they are expensive and difficult to support, so they are used less.

3. Distance adjustment device

According to the requirements of different rubber mixing processes, when the mill is working, it is often necessary to change the roller distance. Therefore, a pair of distance adjusting devices should be installed on the frame on both sides of the front roller, and the range of the adjustment is generally between 0.1 and 15 mm. The distance should not be too large, so as to avoid the speed ratio gear being damaged due to poor meshing. The common distance adjusting device has manual distance adjusting device, electric distance adjusting device and hydraulic distance adjusting device;

4, safety brake device

Safety brake device with hydraulic safety device, safety lever electromagnetic control block brake

5, roller temperature adjustment device

According to the requirements of the rubber mixing process, the surface of the mill roller should be kept at a certain temperature to ensure the rubber mixing effect, quality and rubber mixing time.

The roller temperature adjusting device has an open type and a closed type roll temperature adjusting device, and the open type has the advantages of simple structure, good cooling effect, water temperature can be detected by hand, and water pipe blockage is easy to find, and the disadvantage is that the cooling water consumption is large.

The closed cooling effect is not ideal, but the structure is compact and the cooling water consumption is small.

Post time: Jan-02-2020